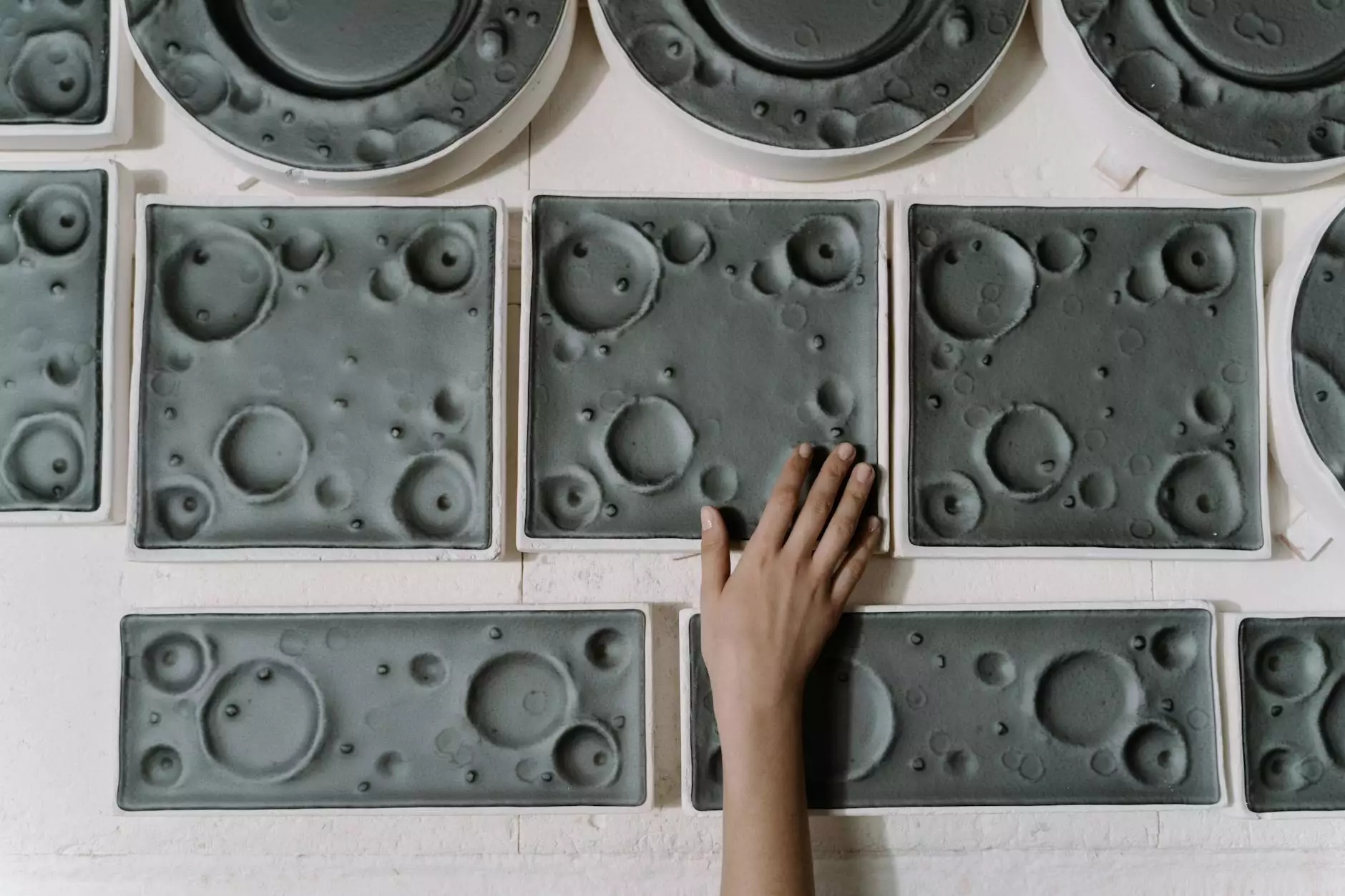

The Advantages of Plastic Part Production

When it comes to manufacturing essential components for various industries, the process of plastic part production plays a crucial role in ensuring efficiency, precision, and cost-effectiveness. At SumiParts, we specialize in providing top-notch services in machining, laser cutting, welding, plastic injection, vulcanized materials, and other industrial supplies, catering to the diverse needs of our clients.

Why Choose Plastic Part Production?

Plastic part production offers numerous advantages for businesses looking to streamline their manufacturing processes and enhance the quality of their products. Here are some compelling reasons to consider incorporating plastic part production into your operations:

1. Precision and Customization

One of the key benefits of plastic part production is the ability to achieve unparalleled precision and customization. Our advanced machining and plastic injection technologies allow us to create intricately designed parts that meet the exact specifications of our clients, ensuring a perfect fit and optimal performance.

2. Cost-Effectiveness

Compared to traditional metal fabrication methods, plastic part production is often more cost-effective due to the lower material and labor costs involved. By choosing plastic components, businesses can save on production expenses without compromising on quality or durability.

3. Versatility and Durability

Plastic parts offer exceptional versatility and durability, making them suitable for a wide range of applications across various industries. Whether you need components for automotive, aerospace, healthcare, or consumer electronics, plastic part production can deliver reliable and long-lasting solutions.

4. Rapid Prototyping and Production

With our state-of-the-art laser cutting and plastic injection capabilities, SumiParts can facilitate rapid prototyping and production processes, allowing for quick turnaround times and efficient product development cycles. This agility enables businesses to bring new products to market faster and stay ahead of the competition.

5. Sustainability and Environmental Benefits

Plastic part production promotes sustainability and environmental responsibility by offering eco-friendly alternatives to traditional materials. Our commitment to using recyclable and eco-conscious plastics ensures that our clients can reduce their carbon footprint and contribute to a greener future.

Explore Our Range of Services

At SumiParts, we offer a comprehensive suite of services in machining, laser cutting, welding, plastic injection, vulcanized materials, and other industrial supplies to meet the unique requirements of our clients. Whether you need precision components, custom prototypes, or high-volume production runs, we have the expertise and resources to deliver top-quality solutions tailored to your specific needs.

Contact Us Today

Ready to experience the benefits of plastic part production for your business? Get in touch with SumiParts today to discuss your project requirements and explore how our services can elevate your manufacturing processes and drive success in your industry.